NOTE: This editorial was originally published in Contracting Business magazine, in the December 1992 issue, on page 4.

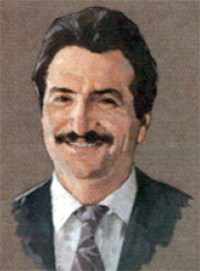

Portrait of Dominick Guarino as Editor-in-Chief of Contracting Business magazine. Painted by Penton/IPC Art Director Lou Grasso in the early 1990s.

We are in the middle of a very exciting time for our industry. We’re finally getting back to the primary reason for our existence: TO PROVIDE COMFORT. After a 20-year derailment triggered by the energy crisis of the early ‘70s, the HVAC industry is showing strong signs of getting back on the comfort track.

If you could get into a time machine, and travel back to the mid to late 1960s and early ‘70s, you would see comfort as the HVAC industry’s primary focus. Efficiency was a small factor then. Emerging technologies were focusing on comfort. Multi-tap blower motor designs allowed two-speed fan operation, humidifiers were gaining popularity, and air condition was becoming standard issue in new mid- to high-end homes. Comfort control centers with sensors and indicators for temperature and humidity control were emerging — some even monitored system performance and air cleaner status.

Then Came the Energy Crisis!

In the early ‘70s, most of the R&D and marketing effort oriented toward comfort was shelved. The new buzzword was energy efficiency. New options sprung to popularity: flue dampers, electronic ignition, programmable thermostats, were just the beginning. Soon manufacturers began churning out technology with higher and higher SEER, AFUE, COP, and HSPF. And until just a few years ago, comfort was kept in sort of a holding pattern.

The trick was to raise the efficiency while maintaining a bare-minimum comfort level. The result: A high efficiency piece of equipment that can be very temperamental. Most heating equipment designers began lowering operating temperature ranges to minimum acceptable levels. When this equipment is coupled with poor or marginal delivery systems, the results are often disastrous.

May homeowners began to complain of a cool, drafty feeling in their homes, regardless of the thermostat setting; particularly in replacement work where many structures are not well insulated, and duct systems are marginal.

The same is true for thousands of heat pumps installed in new homes. Poor, low-cost duct designs, improperly-sized condensers, air handlers, and backup heaters are still the primary cause of discomfort in these homes – a reputation we’re still working hard to live down.

Even today, most HVAC contractors still place more emphasis on selling high efficiency than addressing the customer’s comfort needs. Clearly, there is nothing wrong with efficiency, but unfortunately today it is expected – in fact, it’s federally mandated! Efficiency is fast becoming a commodity. It no longer falls under the category of differentiation. You’d better offer it because everyone else does.

Back to the Future

The good news is we’re finally getting back to the future. Comfort is quickly becoming a primary focus again. Manufacturers are helping to drive this with an emphasis on comfort technology. On the residential front, variable speed compressors, fans, and air handlers coupled with zoning systems can provide unprecedented comfort options. On the commercial side, building management systems coupled with better air distribution technology, humidity control, and air purification, are also forging a new path.

So, where can we go from here? The sky is the limit! In the not-so-distant future, homes could have custom comfort control systems. Such systems would allow the occupant to choose the exact type of environment they want within a specific zone or area of their home or building at any given time.

Perhaps we’ll replace thermostats with comfort control centers using accurate sensors and displays with labels such as Temperature, Air Movement, (year round) Humidity, and Air Quality – even Security Status. The technology already exists, all we need to do is repackage it and make it user-friendly. Some companies have already begun.

Maybe a homeowner or occupant will be able to program combinations of humidity, temperature and air movement – much in the way we program a phone number on our telephones. You could punch in (or call out) a command, and the home’s environment would adjust to your specific needs. This is where our future lies, not in selling $1200 replacement condensers, or by playing the efficiency or warranty game.

A renewed industry is emerging from all this. We’re getting back to the very basics of our profession. Perhaps we should take a pledge – similar to a doctor’s Hippocratic Oath – where people’s comfort is our primary responsibility.

So how do we move forward? To get off on the right foot, we must set aside conventional wisdom, and start from scratch. To help, there is a common sense vehicle available to us called The Quality Process. The first step in any quality process, is to understand your customer’s needs, we can move on to the next step: Developing a set of COMFORT STANDARDS for our industry.

The main problem with design criteria today is that we aim for an average temperature range for the average person, on an average design day. There is no such thing as an average person! That’s like a builder saying to a prospective home-buyer, “You look like an average person, so we’ve decided to install an average kitchen, average carpeting, and average wallpaper in your bathrooms.” That would be ludicrous! Yet the same homeowner is usually offered only an average comfort system which generally performs below their expectations.

Today, Dominick Guarino is CEO of National Comfort Institute, Inc., a company he co-founded in 1997.

Therefore our comfort standards should allow a wide, flexible range of comfort choices to address the ever-changing needs of individual occupants. Much research has already been done on comfort. Particularly on methods of measurement. Perhaps we should dust off some of the old ASHRAE studies done in the late ‘60s and see how the apply to today’s needs. We must develop standards based on what a wide range of people consider comfort to be rather than an average of what works for most.

Once we establish the standards, we must make an ongoing effort to update them as our society’s definition of comfort changes. This data will help us establish new benchmarks for our industry. If we take the time to create these benchmarks, we’ll experience a major departure from traditional system design and installation. We’ll undergo changes from the way we perform load calculations, to the way we approach equipment selection, air and water distribution, and how we select control systems.

As this transformation take place and we become true comfort experts, the serious people in our industry will again have something of great value to offer. They will sell the benefits of a good comfort system, not hardware features. This value will distinguish them easily from the fly-by-nights, or the fast-food-like box-pushers that plague us today. This approach will allow companies to recapture the profit margins they justly deserve.

In this and future issues of Contracting Business, we will publish articles about the companies that have already begun the shift to selling comfort. We will also feature technologies and tools you can use to become a leader in the comfort revolution. It’s time to take your company Back To The Future!

NOTE: In April 2005, Dominick revisited this topic in his Contracting Business magazine LAST WORD column. Read his “Comfort Revolution Revisited,” here.

Pingback: The HVAC Comfort Revolution Revisited: Performance-Based ContractingNCIBlog.com