The Thermostatic Expansion Valve (TEV) has become the refrigerant metering device of choice for most HVACR manufacturers in the past decade. Over time, countless valves have been needlessly replaced because of low airflow affecting their operation.

A basic understanding of TEV operation helps tie the effects of low airflow to proper operation of the valve. Let’s look at how a TEV is supposed to operate and what occurs when airflow across the indoor coil is low.

Basic TEV Operation

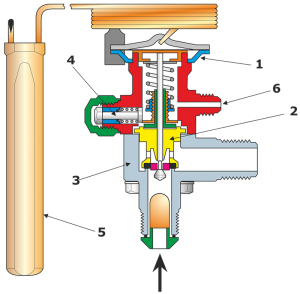

A Thermostatic Expansion Valve (TEV) (1) Membrane housing, (2) Interchangeable adapter, (3) Valve housing, (4) Spindle for adjusting static superheat, (5) Refrigerant-filled bulb, (6) Port for external equalization.

The main purpose of a TEV is to control the flow of liquid refrigerant into the indoor coil of an HVAC system. The TEV is designed to meter refrigerant into the indoor coil at the same rate as it is boiled off. This is important to remember when considering the impact of low airflow.

The TEV meters refrigerant by maintaining a certain amount of superheat as refrigerant goes back to the compressor. For most residential applications, superheat is typically in the 8 to 12 degree range, though this value can certainly vary by equipment manufacturer.

The valve senses three pressures to maintain superheat. They are:

- The pressure exerted by the refrigerant charge in a remote sensing bulb on the diaphragm mounted on top of the valve body.

- The pressure exerted from the refrigerant pressure in the indoor coil.

- The pressure from the spring in the TEV.

As outlet refrigerant temperature of the indoor coil gets warmer, the temperature in the sensing bulb expands causing the diaphragm to move down. This opens the valve and lets more refrigerant flow through.

The bottom of the diaphragm senses indoor coil refrigerant pressure. As the refrigerant pressure increases, the diaphragm moves up. This closes the valve and allows less refrigerant to flow through the coil. In addition to indoor coil pressure, a fixed spring pressure also acts on the bottom of the diaphragm.

As these three pressures constantly fluctuate, they attempt to maintain superheat from the indoor coil. When fan airflow is set properly, this is easy for the valve to achieve. When fan airflow is low, the operation of the valve becomes erratic due to the refrigerant in the indoor coil being boiled off too slowly.

Low Airflow and Indoor Coil Heat Load

As airflow drops below an acceptable range across the indoor coil, the heat load on the coil starts to decrease due to less heat being transferred from less airflow. The refrigerant then boils off at a much slower rate than called for by the system design.

While this takes place, the outlet temperature of the indoor coil starts to drop rapidly. This rapid temperature drop causes the valve to close off due to overfeeding. Refrigerant flow through the coil drops as the valve closes.

The coil is now starved for refrigerant due to the valve underfeeding. This causes a rise in coil outlet temperature. The valve responds to the rise in temperature and opens back up causing more refrigerant to feed into the coil again. The valve hunts for a stable state.

With airflow being low, the refrigerant is still unable to be boiled off quick enough and refrigerant overfeeding starts over. This cycle of the valve overfeeding and underfeeding continues until the thermostat is satisfied, or the low airflow issue is corrected.

What’s unfortunate is every time the valve overfeeds, there is a potential for flood back at the compressor as the valve is searching for a stable point. When the valve underfeeds, the compressor is denied the proper cooling it needs to keep from overheating. After a period of time, the compressor will finally give out and fail due to repeated, long-term abuse.

TEV Hunting

Hunting typically shows up as fluctuations in refrigerant pressure and refrigerant line temperatures. Superheat will decrease and increase as the valve is searching for a point of stabilization. You need to measure both refrigerant pressures and temperatures to uncover this defect in operation.

Checking Fan Airflow

If you encounter a TEV hunting, the first thing to do is check fan airflow, not replace the valve. The easiest method to check fan airflow is to measure total external static pressure and fan speed, then plot fan airflow using the manufacturer’s fan tables. This helps you determine whether lack of airflow across the indoor coil is hindering proper operation of the TEV. It also can help you diagnose the true cause of erratic TEV operation.

Perfectly fine TEVs have been replaced due to overlooking fan airflow. Their “misbehavior” is caused by the conditions they are operating under. Before replacing your next TEV, take a closer look to ensure there isn’t more or less going on than you may assume.